At the threshold of intelligent upgrading, the logistics industry is ushering in earth-shaking changes, and robots will become a well-deserved protagonist of the logistics industry...

In recent years, robotics technology has become increasingly mature, the market scale has continued to expand, and the industry's development prospects are generally optimistic.

With the development of the Internet of Things, various information gradually accumulates in the network. Using these data, it is possible to realize the possibility of robot services in real life.

For example, Hitachi's human coexistence robot "EMIEW3" can aggregate data obtained from various sensors to the IT substrate of a cloud computing platform through the network, and implement rich interactive functions through commands to provide various services.

The application prospects of this type of robot are very broad and have strong scalability. If matched with intelligent systems with remote sound, image, and language processing capabilities, they can provide higher-level services to humans in public facilities and other occasions in the future.

In addition, Hitachi also participates in and leads the formulation of UAV rules, builds demonstration sites necessary for UAV development, and promotes the research and development of technologies related to UAVs and Lumada, using UAVs to solve more social issues and advance Mankind enters the era of drones as soon as possible.

At the same time, the in-depth integration of robotics and various industries also exploded with amazing imagination. Among them, the impact of robotics on the logistics industry is particularly far-reaching.

In the past ten years, driven by emerging industries such as e-commerce, China's logistics industry has experienced a golden period of development, and the scale of the industry has grown rapidly. However, China's logistics industry has long-standing problems such as low technology content and a large amount of idle capacity. With the decline of e-commerce dividends, the logistics industry urgently needs to find new growth points.

The popularization of emerging digital technologies also provides an opportunity for the transformation and upgrading of the logistics industry. Under the guidance of robotics, the logistics industry may usher in a new change, and a change is ready to take place.

01New era of intelligent logistics

How to successfully break through the new wave of technology? For the logistics industry, the answer to this question is undoubtedly of profound practical significance. In fact, for the entire logistics industry, after e-commerce has developed to a certain scale, logistics is the core competitiveness of enterprises to stand out.

At present, my country's logistics industry is transforming from labor-intensive to technology-intensive, from traditional models to modern and intelligent upgrades.

Behind this is the large-scale application and popularization of emerging technologies such as artificial intelligence and the Internet of Things, which brings new opportunities to the development of the logistics industry, and the era of intelligent logistics is about to emerge.

Starting from the pain point, from the perspective of the industry itself, as China's demographic dividend is gradually disappearing, labor costs are rising rapidly, and at the same time e-commerce business volume is rising sharply, e-commerce companies often face massive SKUs and orders of hundreds of millions of dollars.

At the same time, the normalization and long-term prevention and control of epidemics objectively requires logistics companies to realize intelligence and automation, which is the only way for the industry to transform and upgrade, improve quality and efficiency.

Intelligent logistics equipment has obvious advantages in saving warehouse space, improving logistics efficiency, and flexible processing, and it is increasingly favored by enterprises.

Smart logistics is an extremely imaginative huge blue ocean market, and when you dismantle the entire logistics chain, you will find that every link is promising.

For example, in the process of intelligent transformation of the logistics industry, the research and development and application of robotics is a typical representative.

With the arrival of the smart wave, robot foundry has gradually penetrated into all areas of society. As an important infrastructure for e-commerce, the logistics industry is no exception.

At present, intelligent robots with sorting, handling and other functions have become a hot spot in the logistics industry. They are booming, covering all logistics operations, and are widely used.

Looking back at every evolution in the history of the logistics industry, there are shadows of new technologies flickering. For example, Hitachi, a Fortune 500 company, relied on its technology and experience in OT (control technology), and took the lead in the development and deployment of robotics as early as the 1960s.

In the process of technology development for more than half a century, Hitachi has created value through collaboration with customers. At all levels of social life, Hitachi is providing customers with innovative value based on a wide range of robots.

Among them, Hitachi Robotics has rich practical experience and technological accumulation in the exploration and application of logistics field.

From the perspective of robot technology evolution, the development of robots used in logistics has mainly gone through three stages so far.

The first stage of logistics robots is mainly equipment based on conveyor belts and related machinery, collectively referred to as robot prototypes, which enables the industry to transform from manual to automation.

The logistics robots in the second stage have simple automatic sorting and handling capabilities, while the logistics robots in the third stage are more intelligent and integrate big data and machine learning algorithms. The logistics robots in this stage are mostly warehouse robots.

It can be said that at the threshold of intelligent upgrading, the logistics industry is ushering in earth-shaking changes, and robots will become a well-deserved protagonist of the logistics industry.

As the key man who has run through and led the entire robot technology development process and even the application practice of logistics robots, it is because of the continuous exploration of collaborative innovators like Hitachi that we can quickly enter the new era of intelligent logistics.

02 The ambition of "unmanned warehouse"

The pinnacle of the industry in the field of smart manufacturing is the "black light factory", also known as the "smart factory", which can directly turn off the lights and leave the factory, handing over the factory to computer control and automation without manual operation.

36Kr believes that the industry pinnacle in the field of intelligent logistics is the so-called "unmanned warehouse". The warehouse is handed over to robots to automatically sort, pick up, and move goods without manual operations.

If you want to achieve "unmanned warehouse", it is actually not easy, because the industry itself has strong technical barriers to competition.

If there are thousands of logistics robots operating at the same time, how to ensure that they avoid congestion and collisions are technical challenges that need to be overcome.

This requires an effective combination of software and hardware technologies, and continuous iteration and innovation in long-term applications to achieve the goal, which is difficult to achieve without years of technology and experience accumulation.

In the process of continuous formation of logistics robot technology, Hitachi, who has rich practical experience and deep understanding of logistics robot technology research and development and application, is also constantly exploring and innovating.

In 1963, Hitachi developed a dual-control remote operation device. In 1975, it developed and manufactured the first Japanese arc welding robot. In 1990, it developed and manufactured a 4-legged walking robot...

Around 2003, Hitachi started to develop an automatic mobile logistics transportation system with the goal of intelligence again. In 2015, Hitachi developed a logistics robot in the true sense: "automatically controlled mobile dual-arm robot."

The robot is equipped with two industrial robotic arms, supplemented by mechanical claws with grasping and adsorption functions, and with sensors that can locate, take out and move its position and products.

From the effect point of view, it is not a human but is better than a human, able to move around in a cramped warehouse flexibly and quickly, intelligent and efficient.

The successful development of this intelligent robot is also due to Hitachi’s linkage braking technology, which has played a key enabling role.

According to reports, this technology can measure a lower limit of information and action instructions, coupled with multiple program linkage, so as to achieve the robot to complete the extraction and transportation of various commodities.

In addition, in 2009, Hitachi also successfully developed an intelligent transport vehicle that can move on a predetermined route by itself. After the upgrade, the transport vehicle also has self-propelled technology that can respond to changes in product display.

If Hitachi's "self-controlled mobile dual-arm robot" is used in conjunction with an unmanned guided vehicle, it is a simple prototype of an "unmanned warehouse".

On this basis, Hitachi has also carried out the development of a logistics control center, which uses omni-directional cameras to perform three-dimensional imaging to realize visual management and monitor warehouses.

We found that, as an advanced enterprise with deep accumulation in the software and hardware of intelligent robots, before the era of intelligent logistics really arrived, Hitachi had already established an ecosystem with a bunch of ace technologies and equipment in hand.

This includes jigsaw puzzles such as "self-controlled mobile dual-arm robot", "intelligent transport vehicle" and "logistics control center". If they are put together, it is equivalent to directly getting the smart key to open the door of "unmanned warehouse" .

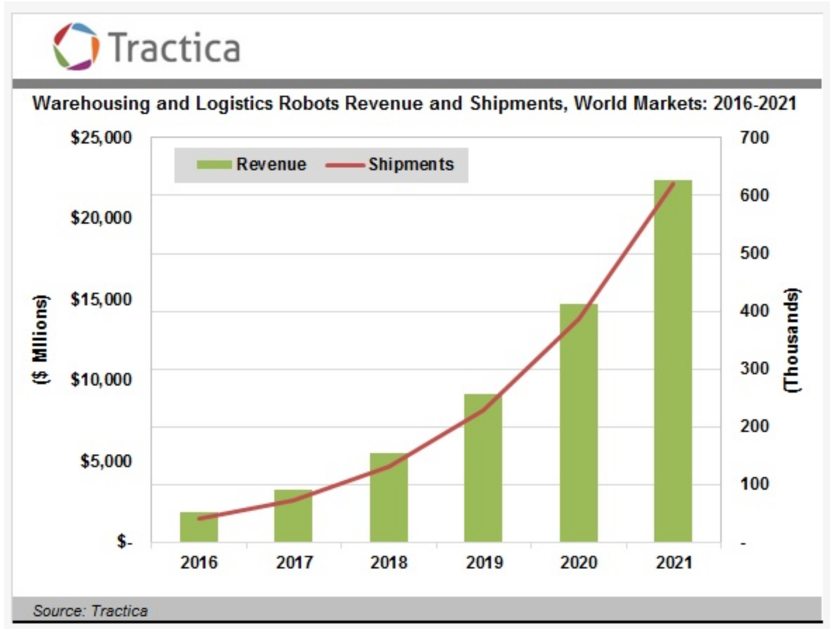

According to data from the "Global Market Analysis and Forecast of Warehousing and Logistics Robots" released by the authoritative organization Tractica in 2017, by 2021, the global shipments of warehousing and logistics robots will surge from 40,000 units in 2016 to 620,000 units. At the same time, the industry’s market revenue will grow from US$1.9 billion in 2016 to US$22.4 billion¹.

A company like Hitachi that has software and hardware technologies and equipment as well as core technology will have immeasurable development prospects.

Through Hitachi's practice and exploration, we can see what role one or two robots play in the era of intelligent logistics.

At present, intelligent logistics represented by robots have urgent needs on both sides of the market, but the intelligent logistics industry is still in its infancy, and the initial infrastructure requires a lot of investment.

Therefore, only relying on the spontaneous entry of logistics vendors in the market will inevitably be difficult to promote the rapid development of the intelligent logistics industry, and it is also necessary for all parties to collaborate and innovate.

03 Hitachi social innovation to make the world full of vitality

In fact, intelligent logistics is only an important field for the application of robot technology. In the real world, a variety of robot technologies have also made important contributions in various fields of society, and have huge application requirements and room for expansion.

In this process, Hitachi’s “social innovation” plays a key enabling role. By solving all the social problems we face, we will gather global intelligence and creativity to help people realize the beautiful life they yearn for as soon as possible. The future glows with more vitality.

Robotic Simulation Services (RSS) by FS Studio, founded in 2018 in San Francisco, embraces the vision of furthering innovation and technology. Fusing the mastery of advanced 3D game development with years of embedded development experience has positioned us uniquely on the cutting edge of 3D Interactive Spatial Computing for Enterprise and Industry 4.0. Partnering with cutting edge robotics and sensor companies we create fully customized, high definition, Sim to Real environments and digital twins to enable and accelerate the development of intelligent machines.Robotic Simulation

ReplyDelete